Textile fibres, the fundamental elements or building blocks of fabrics, have a fascinating origin. It is believed that to seek shelter and protection against natural factors, early humans discovered the utility of fibres like flax (linen), cotton and wool. Although the perishable nature of natural fibres makes it a daunting task for archaeologists to trace the exact origins, the general belief is that textiles are as ancient as the civilisations.

In this article, we will understand the basic properties and categories of textile fibres.

Table of Contents

- Definition of textile fibres

- Monomer and Polymer

- Classification of textile fibres

- Natural fibres

- Man-made/manufactured fibres

Definition of textile fibres

According to the Textile Fiber Products Identification Act (TFPIA), the term “fibre” or “textile fibre” means,

a unit of matter which is capable of being spun into a yarn or made into a fabric by bonding or by interlacing in a variety of methods including weaving, knitting, braiding, felting, twisting, or webbing, and which is the basic structural element of textile products.

In simpler terms, any substance which is linear and pliable with a capacity to be spun or processed in a suitable textile material is a fibre. At scientific levels, textile fibres are polymers (many units) made up of monomers (single unit) of a chemical compound. Generically different fibres have different elemental compositions which give them their specific properties and behaviour.

Monomer and Polymer

Let us try to understand the basic concept of polymerisation which is the process of formation of polymers or textile fibres. Monomer is a Latin term made up of two terms, ‘mono’ meaning ‘one’ and ‘mer’ meaning ‘unit’. Monomer is a small, low molecular weight and chemically active substance which combines to form polymer. Polymer, a latin term made up of ‘poly’ meaning ‘many’ and ‘mer’ meaning ‘unit’, is a high molecular weight, generally linear and chemically stable substance.

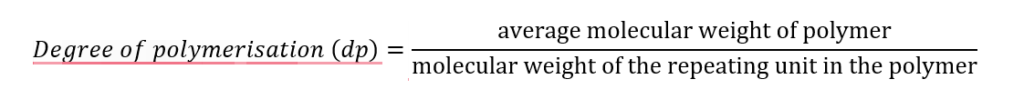

Joining of monomers chemically to form a long polymer is known as polymerisation. The most important feature of a polymer is its length, i.e., the number of monomers joined together to form the polymer, which is determined by its degree of polymerisation (dp). The mathematical expression for the degree of polymerisation is:

Let us understand this equation with an example. Cotton, one of the most common natural fibres, has a dp of 5000. This implies that each cotton polymer or an individual cotton fibre is made up of 5000 repeating units, i.e., monomers. In case of cotton, the monomer is cellobiose.

Classification of textile fibres

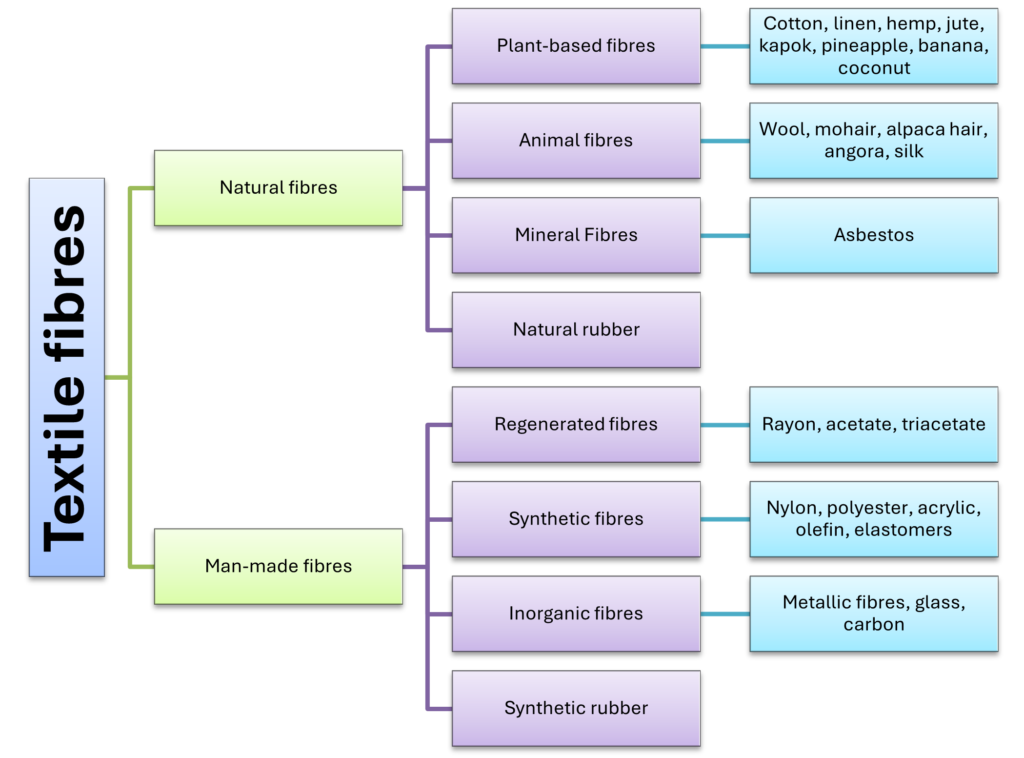

Based on origin, there are two broad categories of textile fibres:

- Natural fibres: Linen, cotton, wool, silk, jute, hemp, banana, asbestos and many more.

- Man-made or manufactured fibres: Nylon, polyester, viscose, spandex, etc.

Natural fibres

According to TFPIA, the term ‘natural fibre’ means any fibre that exists as such in the natural state. Natural fibres are derived from plant, animal, and mineral sources, providing a sustainable foundation for the textile industry. Various types of naturally occurring fibres are:

- Plant-based fibres: These fibres are obtained from different parts of a plant. For instance, cotton is extracted from the seed hair of cotton plants, flax/linen is derived from the stalky stem, and banana fibre is obtained from the leaf. Chemically, the plant-based fibres are cellulosic in nature.

- Animal-origin fibres: Animal hair like wool, angora, and cashmere are the most used as warm fibres. Silk, which is extruded by the silkworms, is one of the most luxurious fibres. Being of animal origin, these fibres are generally protein in nature.

- Mineral fibres: These fibres are obtained from different mineral resources and are not quite common. Asbestos is an example of mineral fibre which is extracted from the rocks found in Italy, Canada and the USA. It is composed of silicate of magnesium and calcium.

- Natural rubber

Man-made/manufactured fibres

TFPIA defines ‘manufactured fibre’ as any fibre derived by a process of manufacture from any substance which, at any point in the manufacturing process, is not a fibre. In simpler terms, the manufactured fibres are produced using different chemicals under controlled conditions. They are generally produced in long continuous forms known as filaments, which can be later cut into shorter-length fibres known as staple fibres, depending on the intended use. The different types of man-made fibres include:

- Regenerated fibres: These fibres are produced by the regeneration of natural raw materials like wood pulp, cotton lint, etc. The most common and widely used fibre in this category is rayon, which combines the comfort of cotton with the sheen of silk. Rayon and its many varieties gained popularity as the fluid fabric, very popular with the masses today.

Another sub-category of regenerated fibres includes fibres like acetate and triacetate which are developed by altering the chemical nature of cellulosic fibres.

- Synthetic fibres: These fibres are completely made from chemicals. There is no use of any kind of natural materials for their manufacturing. These fibres are quite popular due to their high strength and low maintenance nature. The most popular synthetic fibres are nylon, polyester, acrylic, and polypropylene.

- Inorganic fibres: These are the fibres obtained from metals (gold, silver, copper), glass, carbon, and other inorganic substances. These speciality fibres are gaining popularity in the field of technical and medical textiles.

- Synthetic rubber: Varieties of synthetic rubber are neoprene, buna rubbers, and butyl rubbers. These have a wide application in the manufacturing of automotive tyres.

Conclusion

In this article, we have gained an overview of textile fibres. Topics like monomers and polymers have been introduced and will be discussed in detail in subsequent posts. Each textile fibre mentioned here will be discussed individually in the following articles.

Bibliography

Anand, A. (2017). Introduction to Textile Fibres. In D. Rastogi, & S. Chopra, Textile Science (pp. 4-9). Hyderabad: Orient Blackswan Private Limited.

FEDERAL TRADE COMMISSION. (n.d.). SUBCHAPTER V—TEXTILE FIBER PRODUCTS IDENTIFICATION. Retrieved from uscode.house.gov: https://uscode.house.gov/view.xhtml?req=granuleid%3AUSC-prelim-title15-chapter2-subchapter5&edition=prelim

Ghol, E., & Vilensky, L. (2003). Textile Science. Delhi: CBS Publishers & Distributors.